Product details

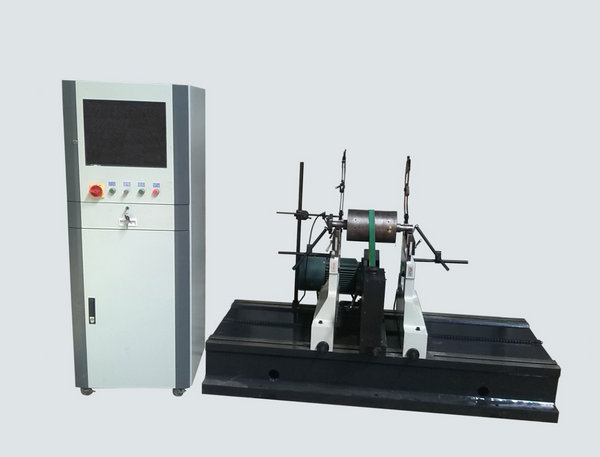

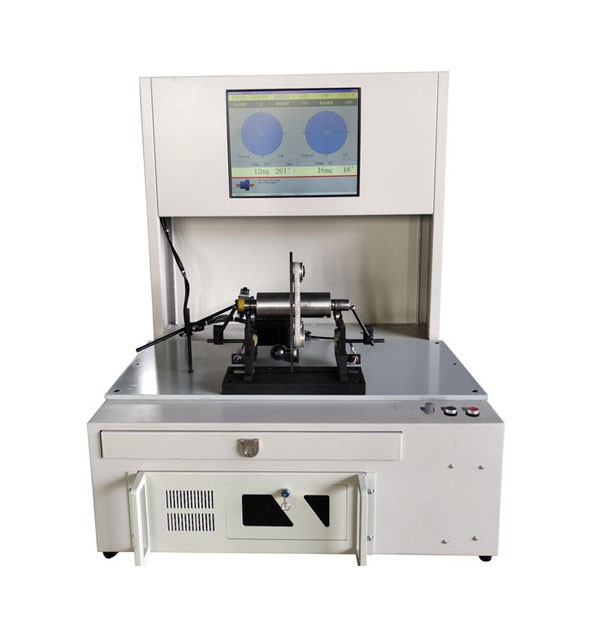

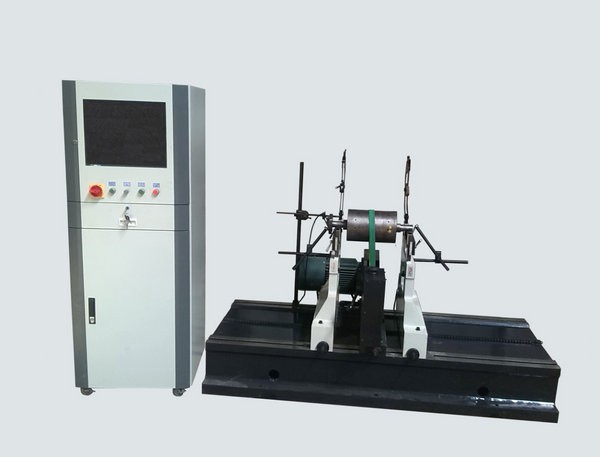

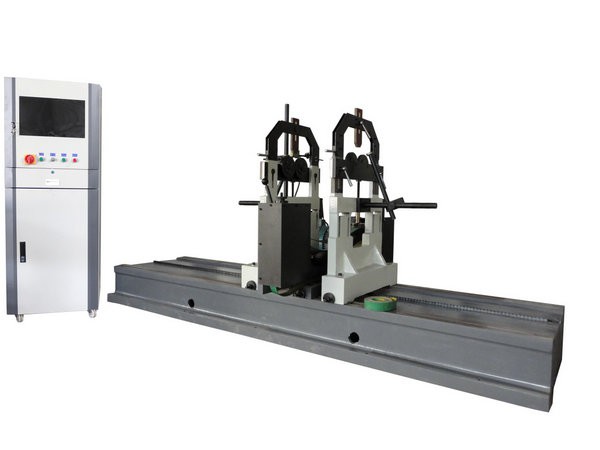

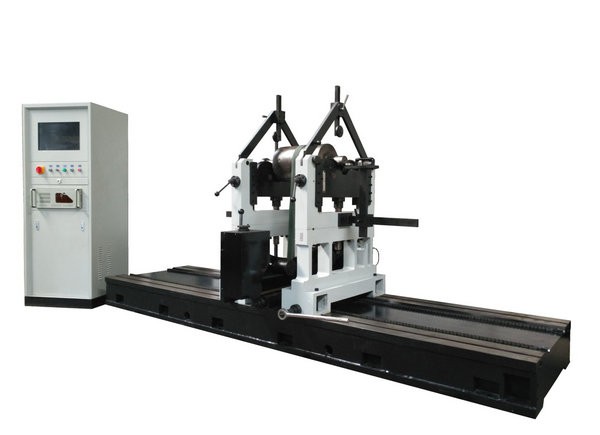

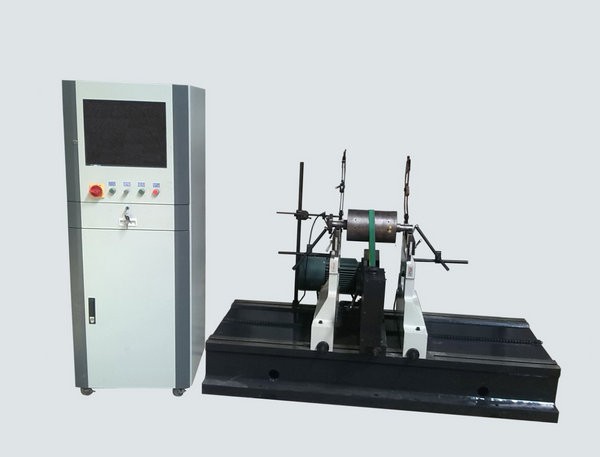

YYQ series is a universal horizontal double-sided dynamic balancing machine with hard support driven by belt drive, so the measuring range of the model is from tens of grams to 10000 kg. Suitable for balancing the motor rotor, roller (either with or without shaft head but without shaft head bigger diameter roller need to customize the institutions), shaft, machine tool spindle rules such as cylindrical rotor balance, balance above kinds parts without tooling, installation fast and convenient equipment measuring accuracy, higher precision is balanced with a universal joint machine; With the suitable jig can also balance the fan, pulley and other parts. Products are widely used in motor, generator, fan, engine, agricultural machinery, textile machinery, chemical, woodworking machinery, papermaking machinery and other industries, can be on one side, two sides and a number of correction surface balance measurement, suitable for shaft, disc type overhanging rotor. It has the advantages of high efficiency, accurate precision, intuitive display and reliable quality. Measuring system ★ industrial control computer, 19 inch LCD (according to customer needs with a touch screen), Windows operating platform ★ with the company's independent development of balance measurement system. General software functions cover all the functions of the domestic mainstream balancing machine software, the operation of all the use of Chinese menu structure, operating steps text prompt; Special software includes: all kinds of automatic balancing machine software, with the function of tracking the Angle of the software, with the function of automatic positioning software, transmission shaft multi-axis joint school software, etc. Wide range of arbitrary workpiece calibration, measurement speed 80 RPM rev test, measurement speed, unbalance of amplitude and phase stability, height to weight ratio and separation ratio, high sensitivity to end with allowable amount of unbalance calculator software, the operator only need to input the allowable vibration of workpiece precision grade, quality, speed, and click on the radius calculation will be able to get to the artifact to allow grams of residual unbalance u completely self-developed software, can according to customer requests to modify or add software functions (such as scan qr code to add the artifact id name to stored in the measurement results, Mechanical parts and control ★ swing drive and bed body with castings, enough rigidity and stability; Swing driving static pressure resistance is strong, under the premise of sufficient equipment driving capacity can generally overload more than 20 percent ★ the roller on the balance machine is made of bearing steel, the overall salt bath quenching hardness reached HRC55; After grinding the supporting face of the roller, then polishing the radial runout of the small roller bearings, so that the workpiece running more smoothly on the measurement signal interference is lower ★ swing frame can move along the bed and can be stopped in any part above the bed, so the equipment can balance between arbitrary length of the workpiece. ★ the belt drive assembly can also be moved along the bed, convenient to drag the appropriate parts according to the workpiece. ★ reliable quality of equipment, the use of frequency conversion speed control system, motor soft start soft stop on the impact of the equipment is small, extended the service life of the equipment. Equipment can work continuously, maintenance is simple and convenient note: Want to know more detail please contact our factory standard configuration parameters of the equipment model YYQ kg - 160 - a workpiece quality range 2-160 ring drag mm diameter range from 30-300 mm diameter workpiece two span 950 mm lathe bed length, 100-1300 mm roller support trunnion mm from 10-1500 balancing speed 90 r/min drag in diameter of 180 mm, 300-1500 infinitely adjustable-speed minimum residual rough measure 0.5 GMM/kg or less amount of unbalance decrement % The above is the standard configuration equipment parameters of our factory, we support the product, system according to the customer's demand on the equipment diameter, length, Roller support workpiece shaft diameter range to do the equipment structure allows reasonable change (such as can be expanded to 90-180) ★ if there is a need for equipment can match the electrical equipment suitable for single-phase AC220V, 50/60hz power supply ★ equipment can increase the Angle with tracking function ★ equipment can increase the reasonable accessories that do not affect the measurement performance, such as protection and weight device