Product details

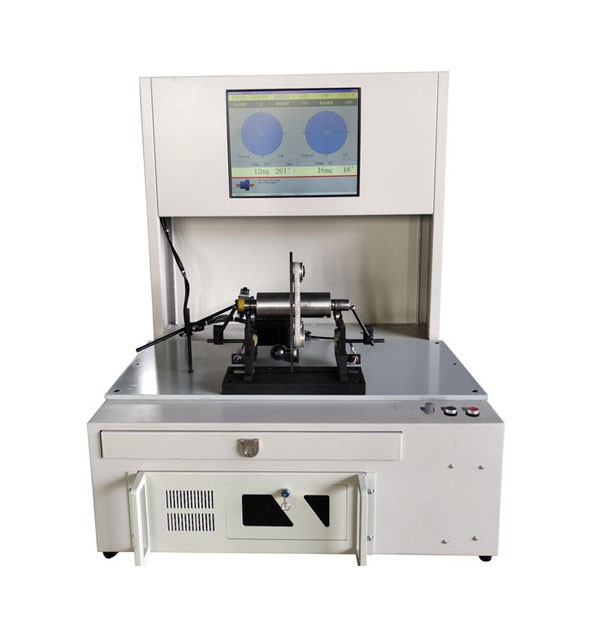

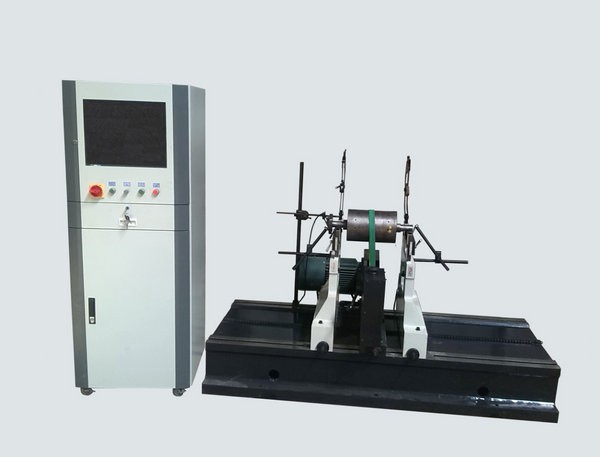

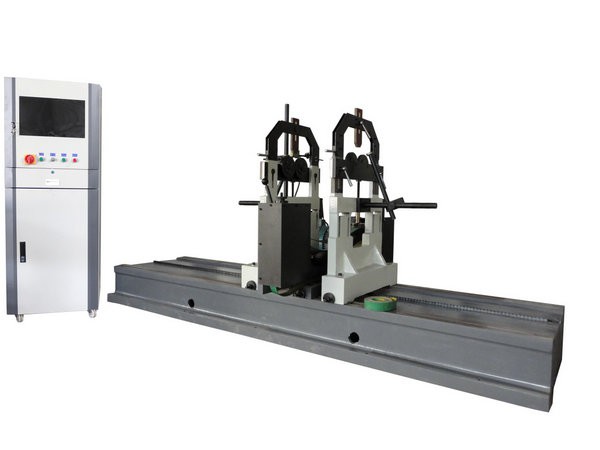

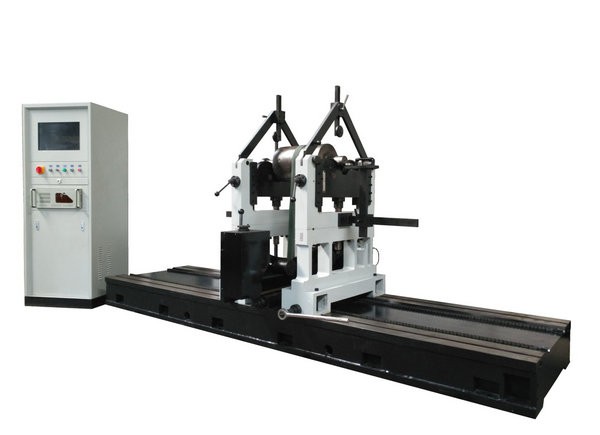

1. Product introduction of yyq-5 (16) A

Yyq-5 (16) A is A horizontal double-sided dynamic balancing machine with ring belt drive and hard support. Suitable for balancing supercharger rotor, small motor rotor, woodworking, small water pump or fan impeller, treadmill drum, runner fan impeller and other workpiece. Balance measurements can be made on single, double and multiple correction surfaces, suitable for shaft and disc type overhanging rotors. It has the advantages of high efficiency, accurate precision, intuitive display and reliable quality.

2. Measurement system

Industrial control computer, 19 "LCD display (can be customized with touch screen), Windows operating platform

★ with the company's independent development of balance measurement system. General software functions cover all the functions of the domestic mainstream balancing machine software, the operation of all the use of Chinese menu structure, operating steps text prompt; Special software includes: all kinds of automatic balancing machine software, with the function of tracking the Angle of the software, with the function of automatic positioning software, transmission shaft multi-axis joint school software

★ measuring system performance is strong: arbitrary workpiece calibration, measuring speed range wide 80 RPM starting, measuring speed block, unbalance amplitude and phase stability, high deweighting rate and separation ratio, high sensitivity

★ software with allowable unbalance calculator, the operator only needs to input the allowable vibration of the workpiece precision level, mass, working speed, and radius click to calculate the number of grams to allow the remaining unbalance of the workpiece

★ software completely independent development, according to customer requirements to modify or add software functions (such as scanning the two-dimensional code to add the workpiece identity name to the measurement results to save for future quality investigation)

3. Mechanical parts and controls

★ bed with HT200 overall casting, two T parallel guide rail. The swing frame is machined by line cutting and matching, with good consistency and rigidity. Equipped with tooling platform, the operator more comfortable

★ with micromotor as the source power, the use of tower motor belt wheel can avoid the same frequency interference with the pulley and workpiece.

★ the ring belt adopts the pressure type structure, the belt hangs on the tight mechanism, the upper and lower workpiece without hanging the belt, convenient and fast.

★ speed regulation system using frequency converter speed regulation, soft start soft stop

Note: please contact us for more information about the equipment

Manufacturer standard configuration parameters

Equipment model yyq-5a yyq-16a

The workpiece quality range is kg 0.1-5 0.3-16

The maximum diameter of the workpiece is mm 500 500

Spacing of two supports mm 60-550 60-550

The diameter range of the belt dragging place is mm 15-200 15-200

Support shaft diameter mm 5-36 5-36

When the diameter of the drag is 100mm at the equilibrium speed r/min, 400-1400 when the diameter is 100mm at the drag

Minimum residual unbalance ≤0.5 GMM /kg ≤0.5 GMM /kg

Unbalance reduction rate % ≥90% ≥90%

Measuring time 10S (related to measuring speed and setting period)

Motor power 0.18kw 0.18kw

Frequency conversion speed regulation frequency conversion speed regulation

Transmission mode ring belt ring belt

Equipment power supply three-phase AC 380V, 50/60hz three-phase AC 380V, 50/60hz

★ the above is the factory's standard configuration equipment parameters, we support the product, system according to the customer's demand for the maximum length of the equipment and the length of the roller support workpiece range to do the equipment structure allows reasonable changes

★ if necessary equipment can be matched with electrical appliances for single-phase AC220V, 50/60hz power supply

★ equipment can be added without affecting the measurement of performance of reasonable accessories, such as protection