Product details

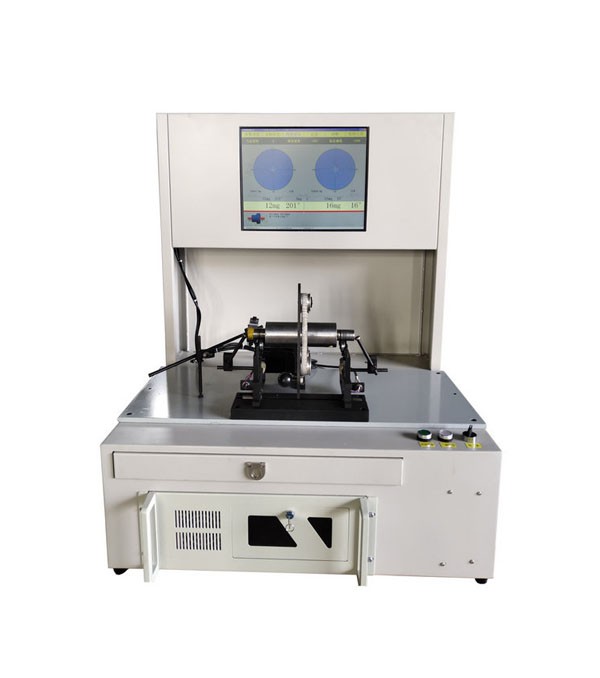

1. Introduction of yyq-5 (16) D balancing machine

YYQ - 5 (16) D is hard bearing ring drive bearing horizontal double dynamic balancing machine, products using roller bearing, a drag ring, at the same time adopt servo motor control Angle of equipment operation and must stop, suitable for the rules of the relatively smooth surface tested balance cylinder type of artifacts, such as an armature, motorized spindle, roller and other treadmill shaft parts, etc. The product solves the problem of manual Angle finding when the belt balancing machine is balanced, greatly improves the weight removal rate and balance efficiency of the equipment, and is more suitable for the factory to batch production.

2. Measurement system

Industrial control computer, 17-inch touch screen, Windows operating platform

★ with the company's independent development of the balance of the automatic positioning function of the special measurement system. Software functions cover all the functions of domestic mainstream balancing machine software; After the software sets the balance speed, the software controls the equipment to automatically reach the set speed without manual intervention

★ the motor starts to measure the speed and the software automatically starts to measure, the measurement completed software control servo motor left unbalance phase point in the designated position, press the command button servo motor will put the right unbalance phase point in the designated position

★ measuring system performance is strong: arbitrary workpiece calibration, measuring speed block, unbalance amplitude and phase stability, high deweighting and separation ratio, high sensitivity

★ software with allowable unbalance calculator, the operator only needs to input the allowable vibration of the workpiece precision level, mass, working speed, and radius click to calculate the number of grams to allow the remaining unbalance of the workpiece

★ software completely independent development, according to customer requirements to modify or add software functions (such as scanning the two-dimensional code to add the workpiece identity name to the measurement results to save for future quality investigation)

3. Mechanical parts and controls

★ bed with HT200 overall casting, two T parallel guide rail. The swing frame is machined by line cutting and matching, with good consistency and rigidity

★ the double motor belt wheel configuration can avoid the belt pulley and the workpiece may produce the same frequency interference.

★ the ring belt adopts the pressure type structure, the belt hangs on the tight mechanism, the upper and lower workpiece without hanging the belt, convenient and fast.

★ ipc and PLC control servo motor running, speed software control, soft start soft stop

Note: please contact us for more information about the equipment

Manufacturer standard configuration parameters

Equipment model yyq-5d yyq-16d

The workpiece quality range is kg 0.1-5 0.3-16

The maximum diameter of the workpiece is mm 500 500

Spacing of two supports mm 60-550 60-550

The diameter range of the belt dragging place is mm 15-200 15-200

Support shaft diameter mm 5-36 5-36

When the diameter of the drag is 100mm at the equilibrium speed r/min, 400-1400 when the diameter is 100mm at the drag

Minimum residual unbalance ≤0.3 GMM /kg ≤0.3 GMM /kg

Unbalance reduction rate % > 90% > 90%

Measuring time 10S (related to measuring speed and setting period)

Motor power 0.75kw 0.75kw

Speed regulation mode software control software control

Transmission mode ring belt ring belt

Single-phase AC 220V, 50/60hz single-phase AC 220V, 50/60hz

★ the above is the factory's standard configuration equipment parameters, we support the product, system according to the customer's demand on the length of the equipment, the roller support workpiece shaft diameter range to do equipment structure allows reasonable changes

★ the device can be uneven marking function

★ equipment can be driven by belt - cutting